Controlling Hazards And Risk

Mechanical Sharp points edges, overload Electrical Insulation damaged or cover broken ;.

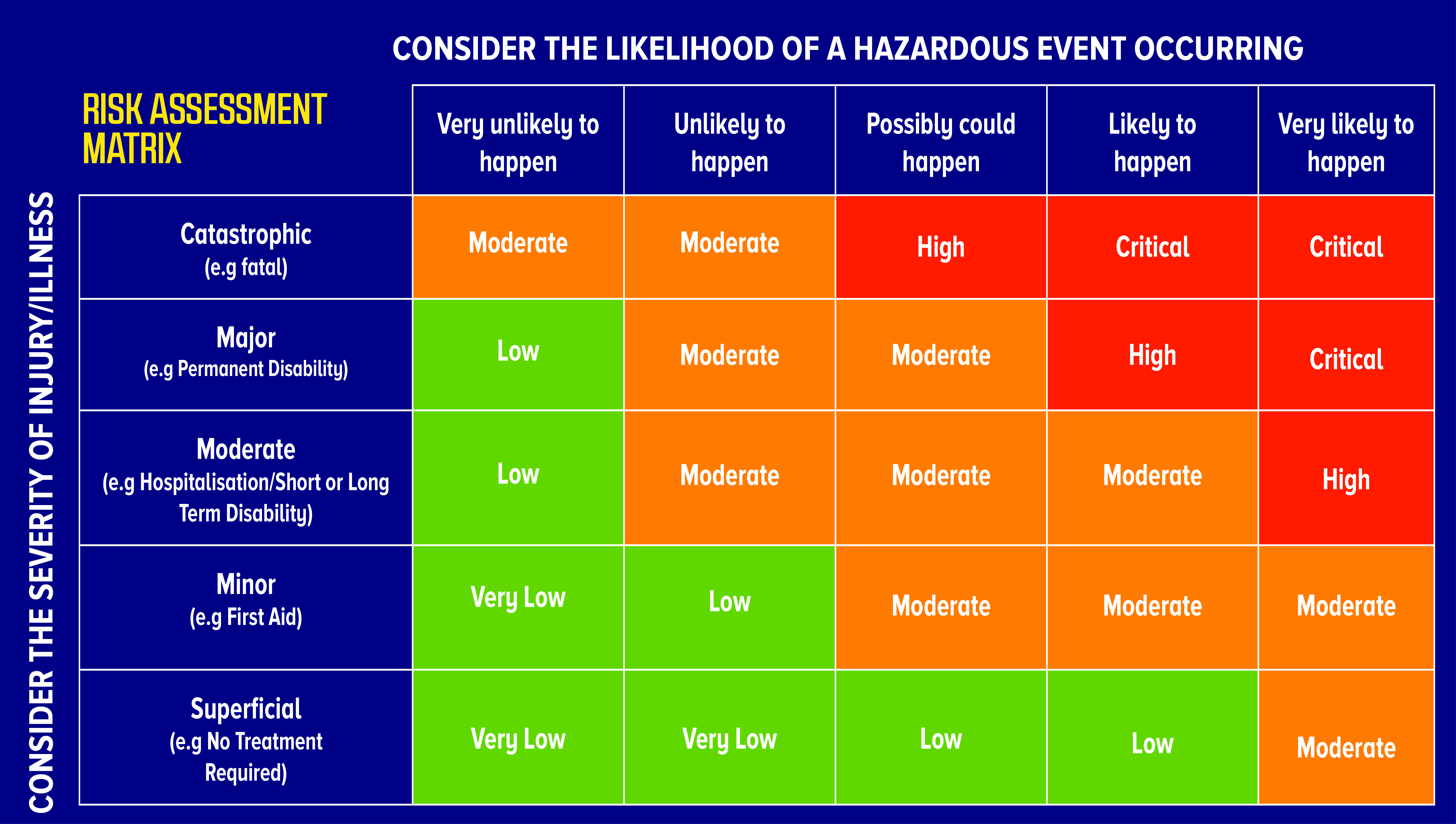

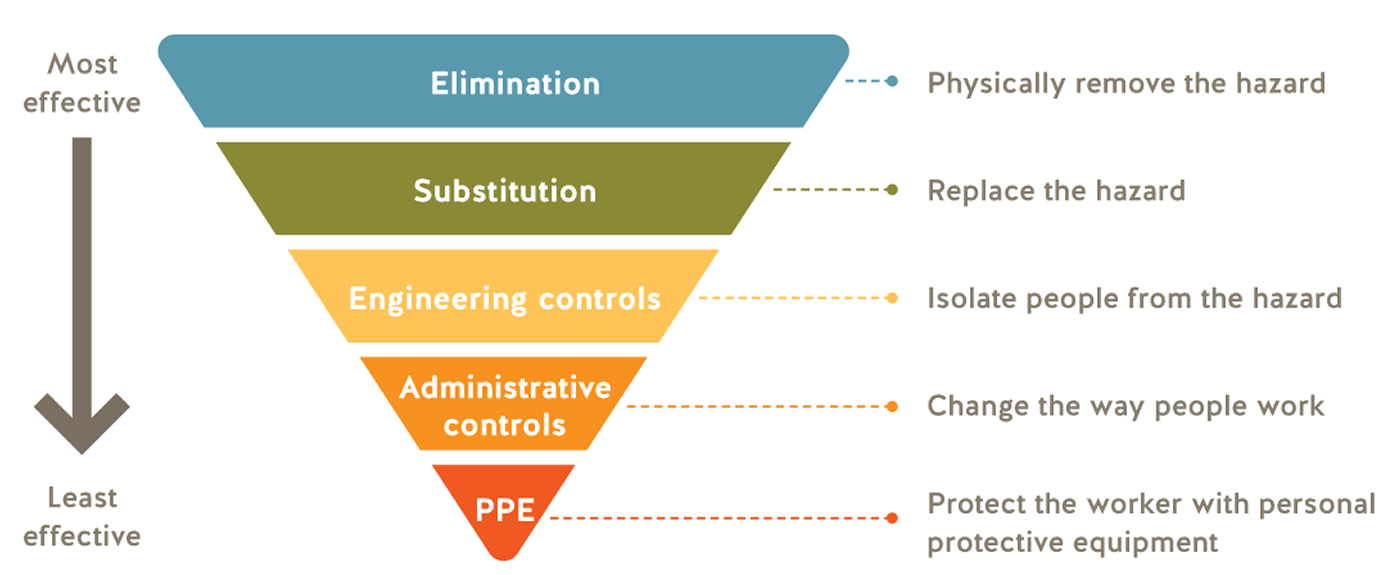

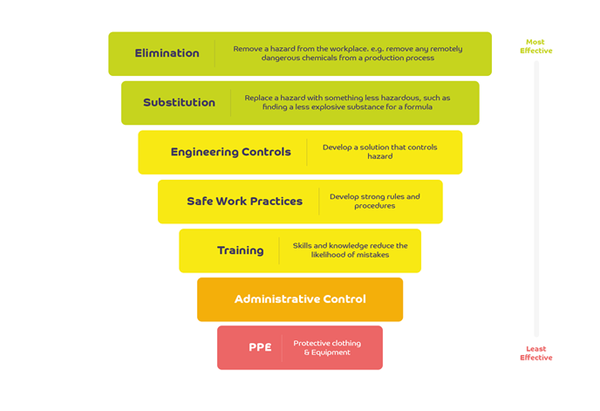

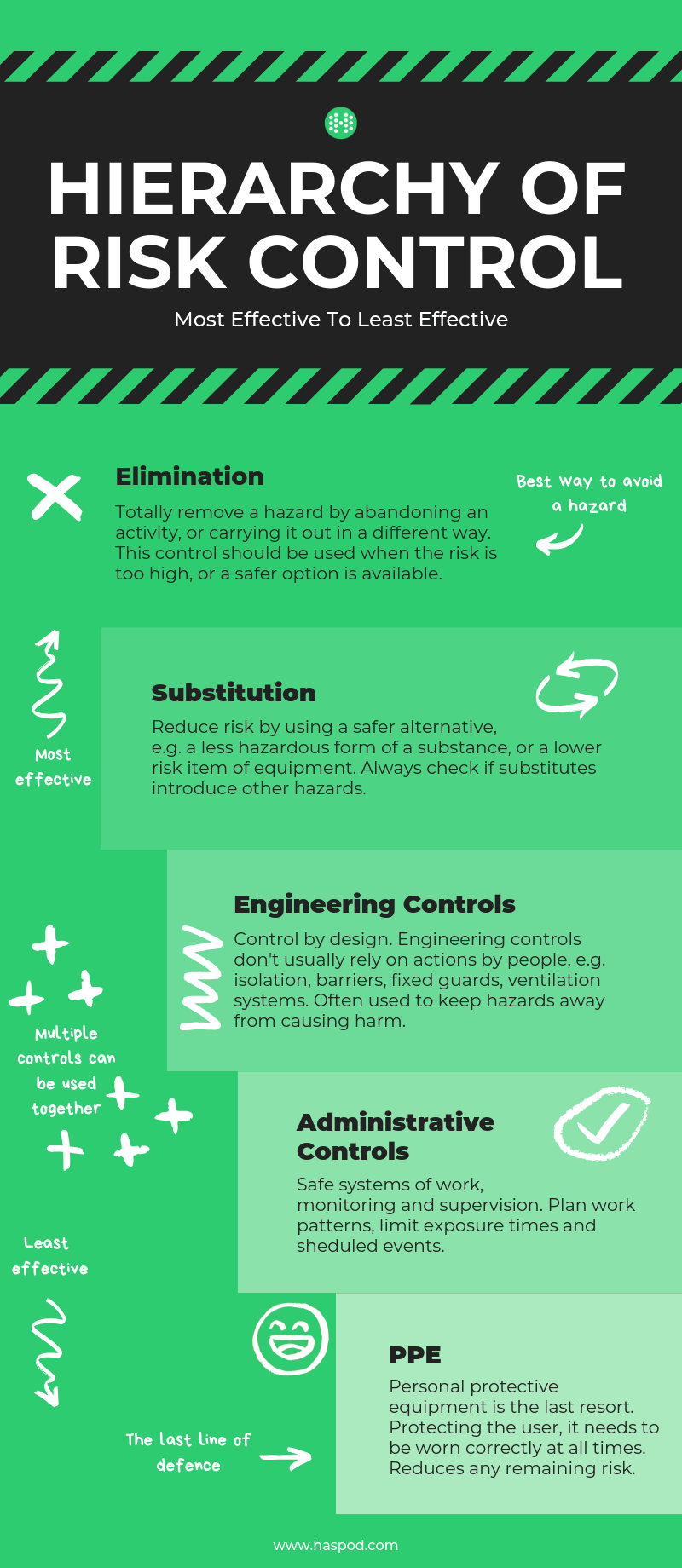

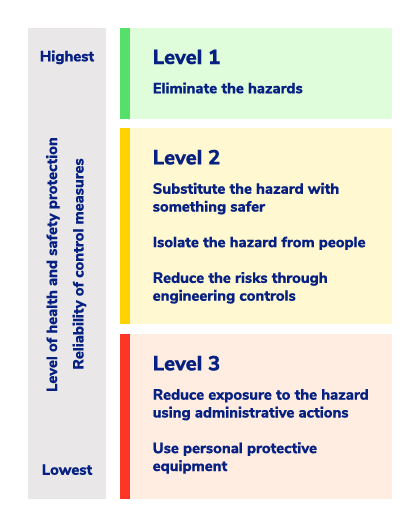

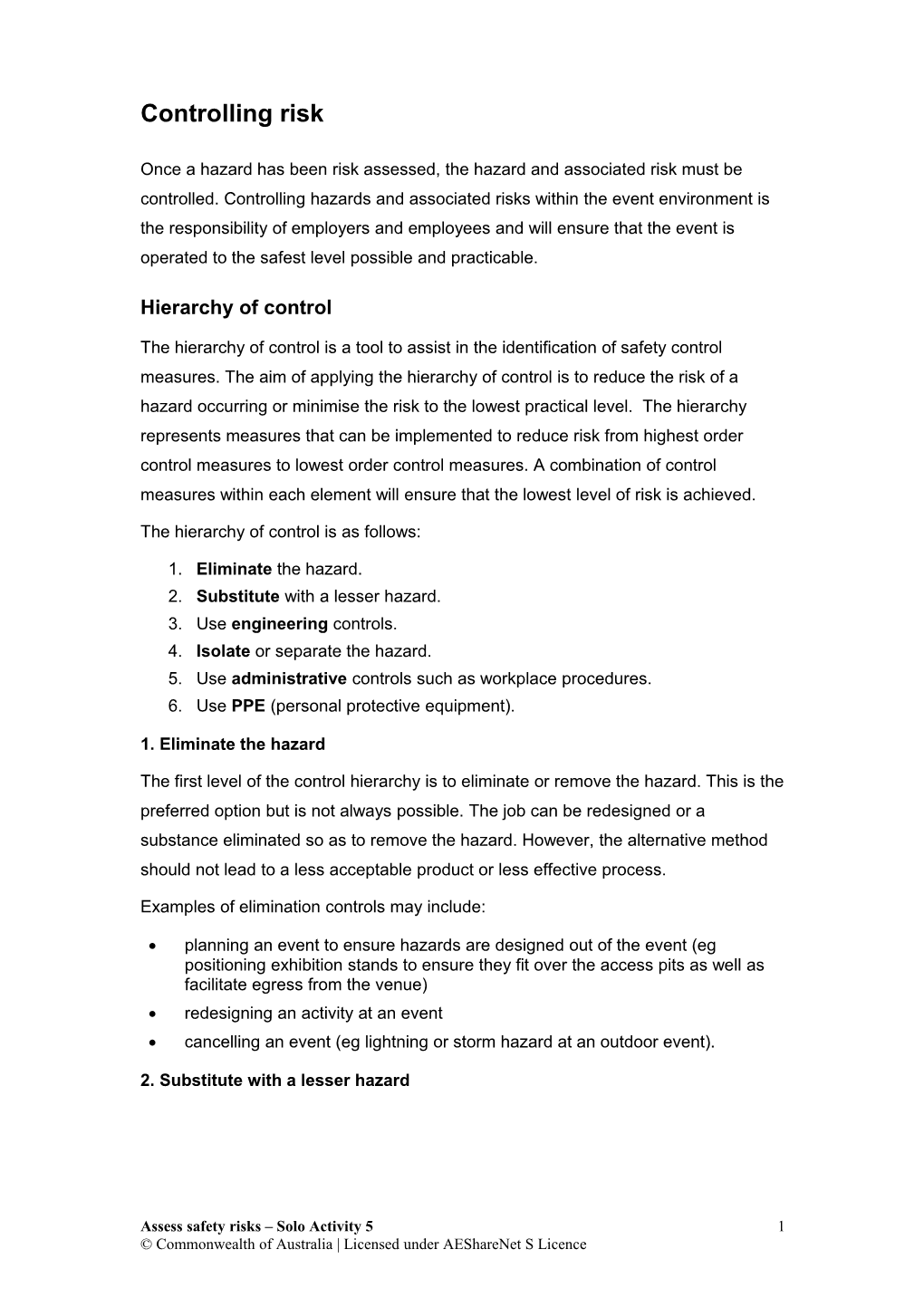

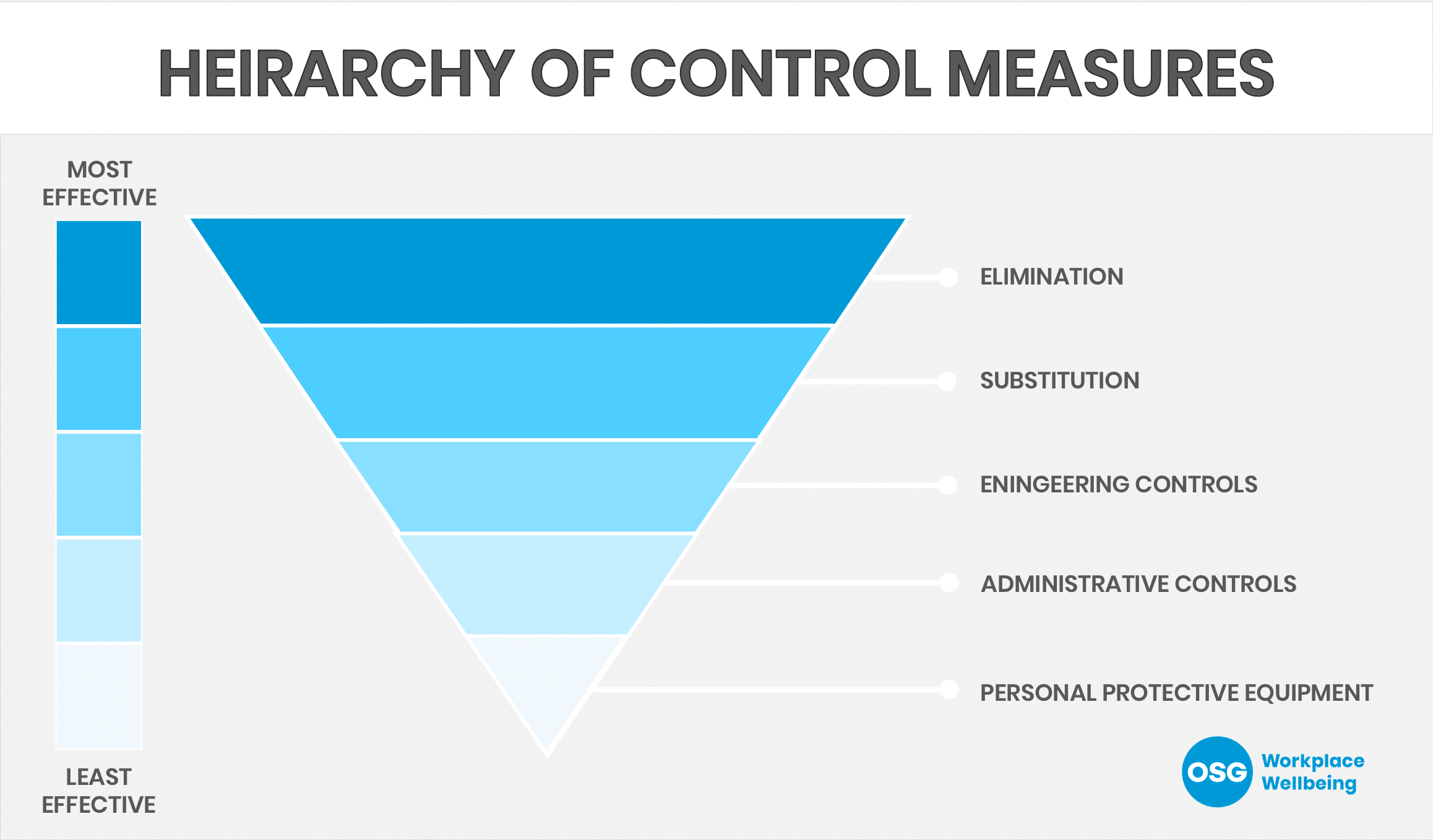

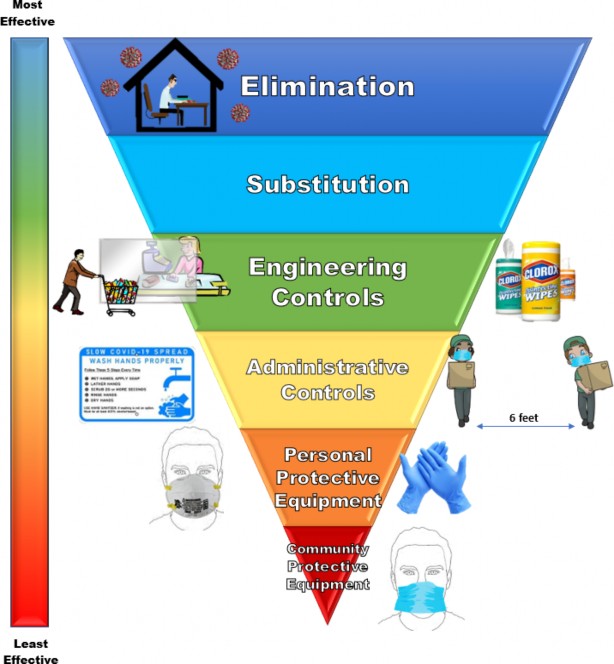

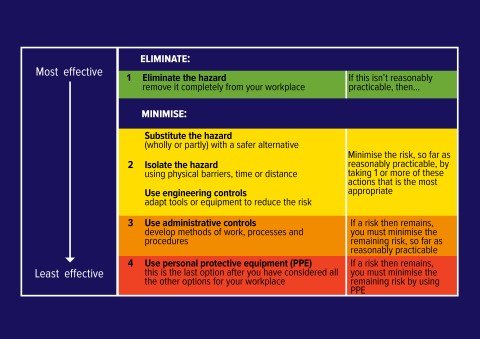

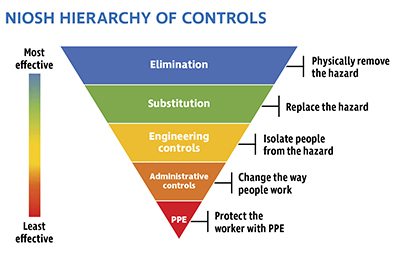

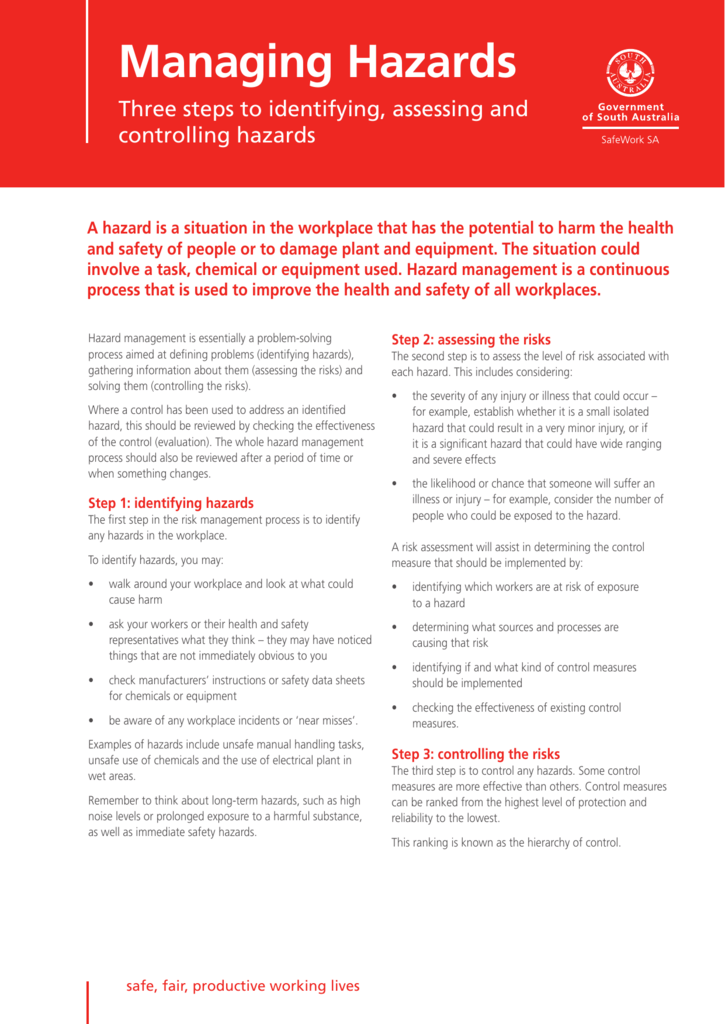

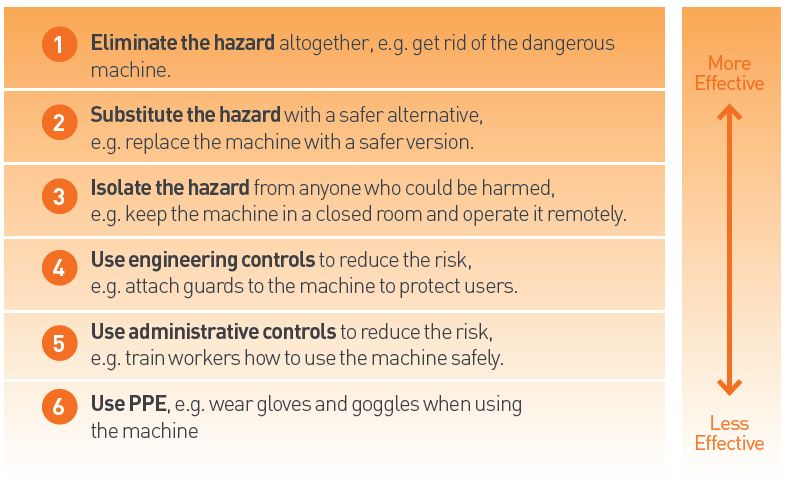

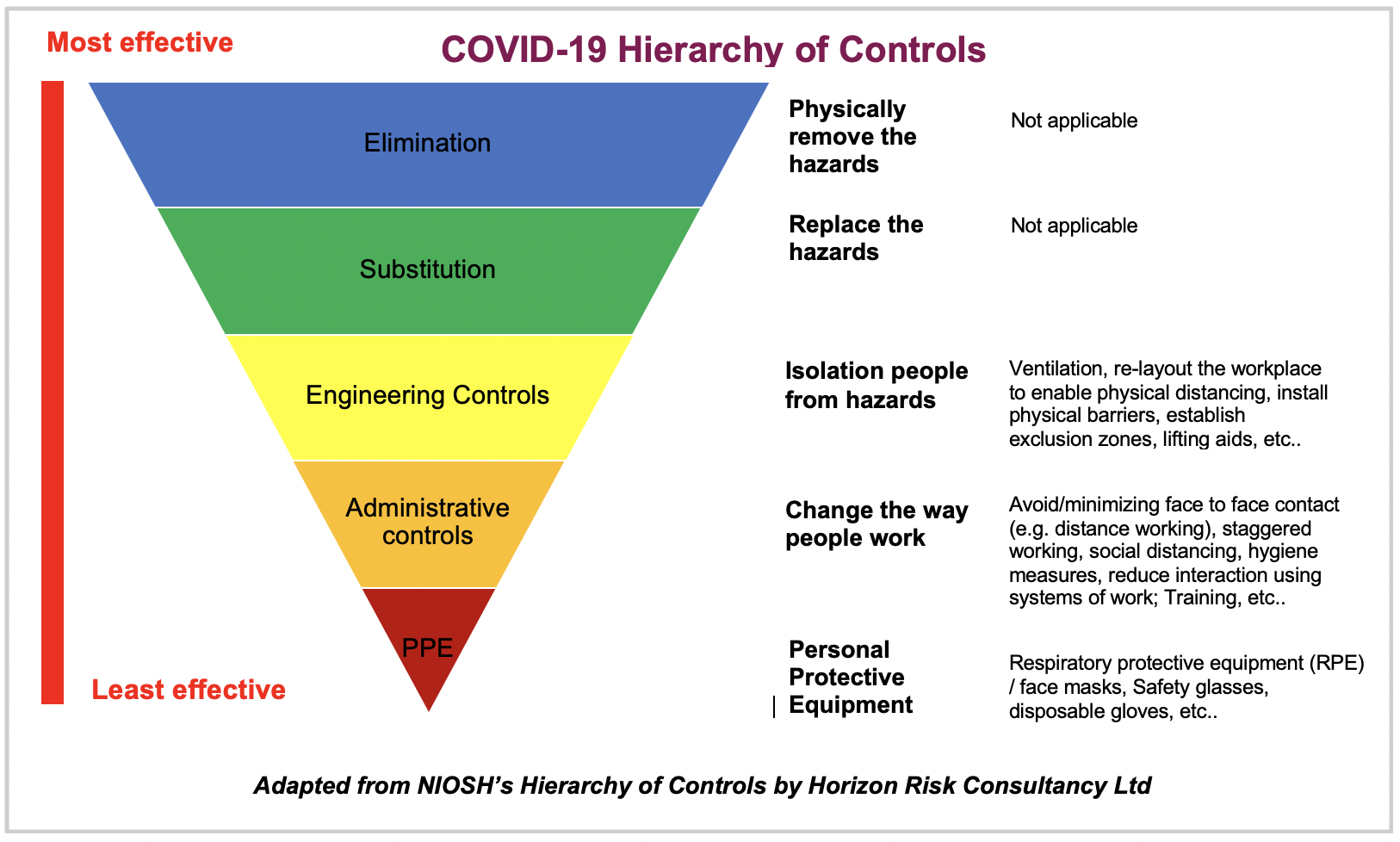

Controlling hazards and risk. If it is not possible to eliminate the hazard, below are 6 steps to determine the most effective measures to control workplace hazards and to minimise risk Step 1 Design or reorganise to eliminate hazards It is often cheaper and more practical to eliminate hazards at the design or planning stage of a product, process or place used for work. A worker is exposed to a number of hazards at work For example, a worker working in extreme hot temperatures is more likely to get dehydrated, while a worker working high above the ground is at risk of falls Hazards are often controlled via what's called the hierarchy of hazard control. Evaluate Evaluating risks is a key step in working with hazardous materials, instrumentation, and equipment A risk assessment will in part examine the probability that an adverse event will occur and the consequence of that event when working with hazardous materials Ultimately, this can help to determine the proper controls that will be needed to avoid the adverse event.

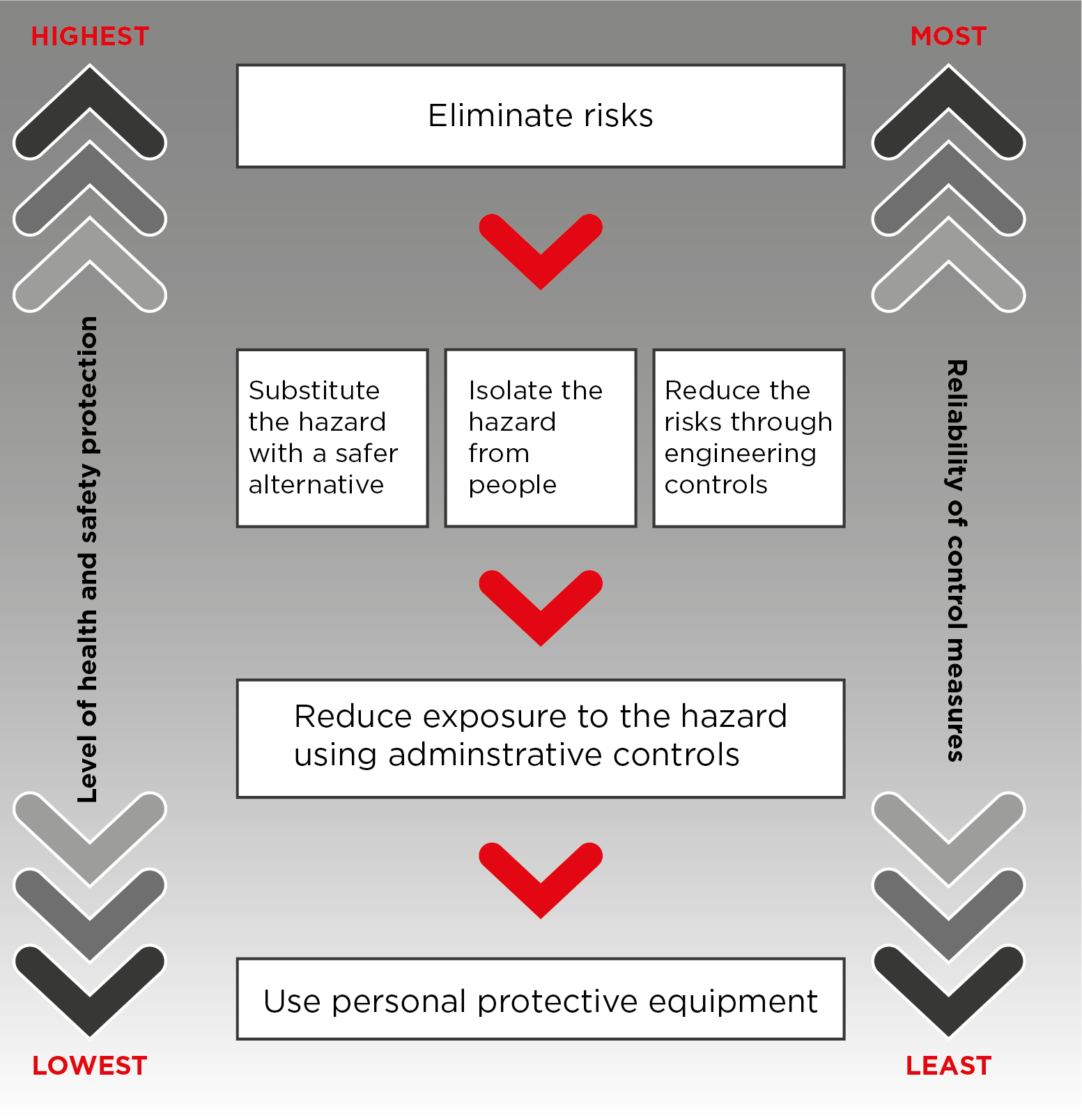

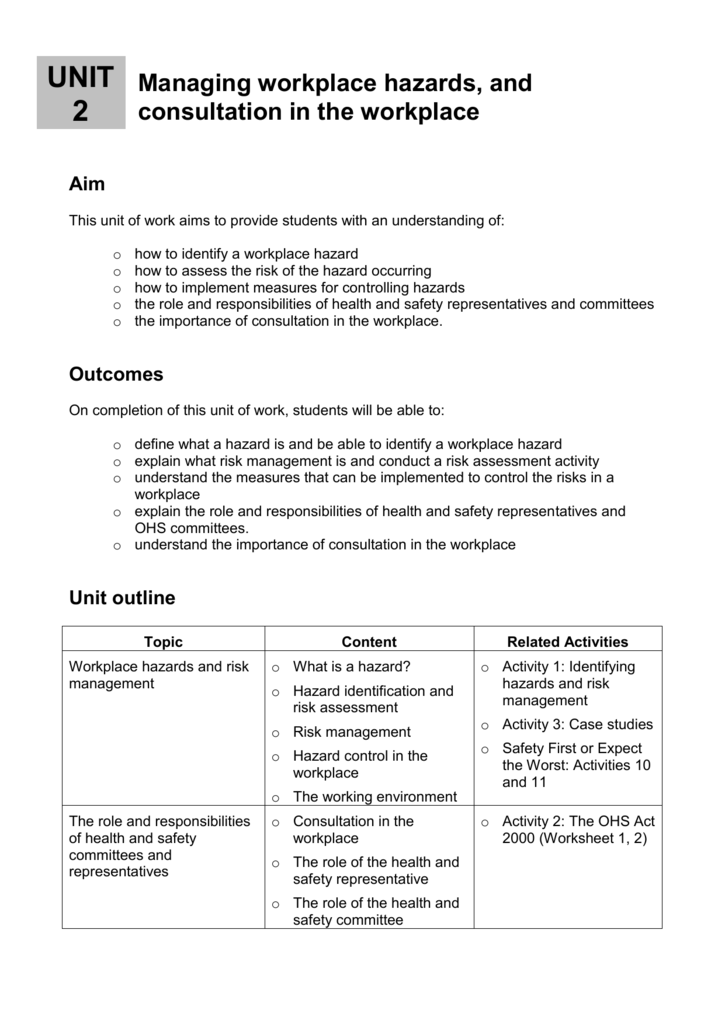

Objectives of the day differentiate hazard and risk identify the types of workplace hazard create a poster showing tips for safety and health at workplace HAZARDS IN THE WORKPLACE THERE ARE MANY THINGS THAT AFFECT THE HEALTH OF A PERSON, SUCH AS ENVIRONMENT, LIFESTYLE, ETC. The hierarchy of controls below is a systematic way to determine the most effective feasible method to reduce risk associated with a hazard Generally, the use of a combination of controls is most effective 3 Develop and maintain a hazard control plan A hazard control plan describes how the selected controls will be implemented. The risk control measure that has the greatest level of effectiveness is elimination Before any other control measures are considered, elimination must be applied first Elimination is the method of totally removing a hazard or hazardous practice from the workplace.

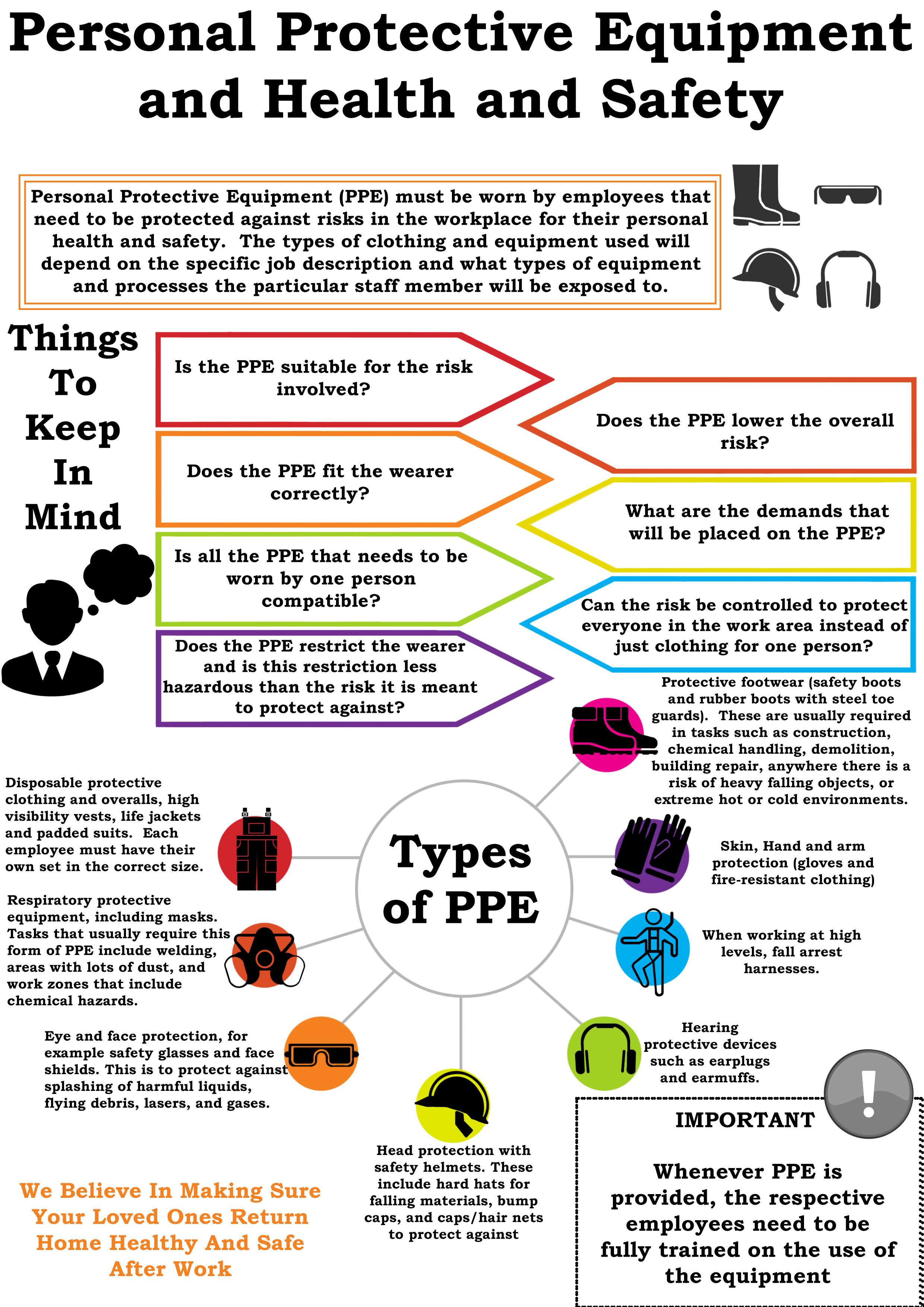

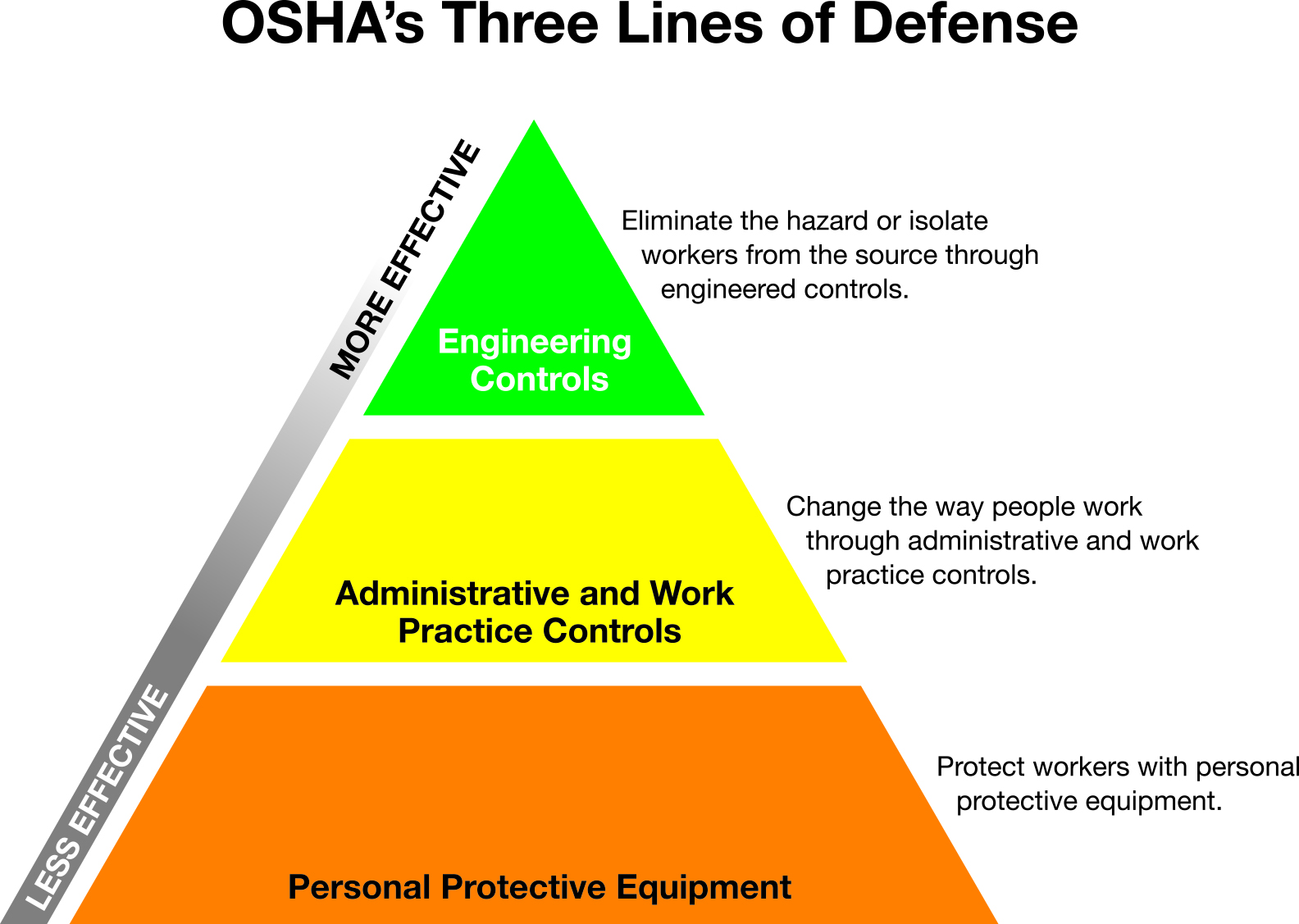

Minimize or eliminate safety and health risks;. Different businesses will have different health and safety risks The risks you need to identify, assess and manage depend on the type of work you do A healthy and safe workplace starts with identifying and understanding what your workrelated health and safety risks are, particularly those that have the potential to cause people serious injury or illness. After lab hazards have been identified and evalutated, all must be controlled to avoid exposure Traditionally, a hierarchy of controls is used to determine how to implement feasible and effective controls for any hazard Control methods at the top of the hierarchy are potentially more effective and protective than those at the bottom.

How to Control Hazards and Risks in the Workplace In controlling the hazards in your workplace, you need to make sure that everything is checked and secured Your employees’ lives are what’s at stake;. A guide for employers, selfemployed people, and those with management and control of workplaces, who have duties to ensure health and safety under the OHS Act 04 This handbook includes steps to controlling OHS hazards and risks;. How to manage the process.

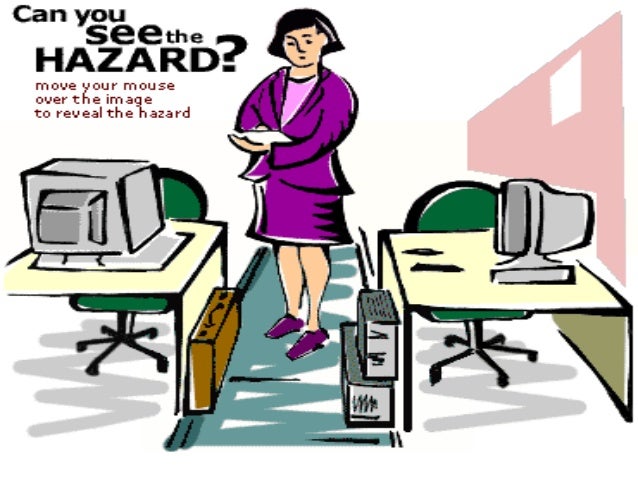

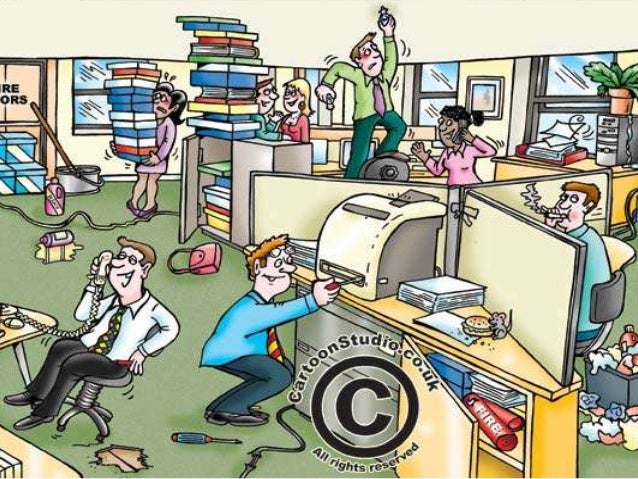

A hazard is something that can cause harm, eg electricity, chemicals, working up a ladder, noise, a keyboard, a bully at work, stress, etc A risk is the chance, high or low, that any hazard will actually cause somebody harm For example, working alone away from your office can be a hazard The risk of personal danger may be high Electric cabling is a hazard. Objectives of the day differentiate hazard and risk identify the types of workplace hazard create a poster showing tips for safety and health at workplace HAZARDS IN THE WORKPLACE THERE ARE MANY THINGS THAT AFFECT THE HEALTH OF A PERSON, SUCH AS ENVIRONMENT, LIFESTYLE, ETC. 14 Classification Potential Sources of Hazards Classification Example of Hazards ;.

Hence you should do it discreetly One wrong move could endanger not only your employee but also your company Follow these steps to keep your workplace safe from risks and hazards. How to implement a system for controlling OHS hazards and risks;. Never mind the ignorant, only the blessed can see a kitchen for what it truly stands for!But then again it surely brings its share of hazards to the house So for all the mums out there, and to the gloating dads who thinks washing a spoon is itself a herculean task, we bring you 10 Common Hazards in the kitchen and how to avoid them.

Control measures include actions that can be taken to reduce the potential of exposure to the hazard, or the control measure could be to remove the hazard or to reduce the likelihood of the risk of the exposure to that hazard being realised A simple control measure would be the secure guarding of moving parts of machinery eliminating the. The risk control measure that has the greatest level of effectiveness is elimination Before any other control measures are considered, elimination must be applied first Elimination is the method of totally removing a hazard or hazardous practice from the workplace. If it is not possible to completely eliminate the risk, controlling your risk may mean that you are taking actions to minimize the risks and hazards within the work environment There are four main methods that can be used to eliminate or minimize these risks – avoidance, loss prevention & reduction, transfer, and acceptance.

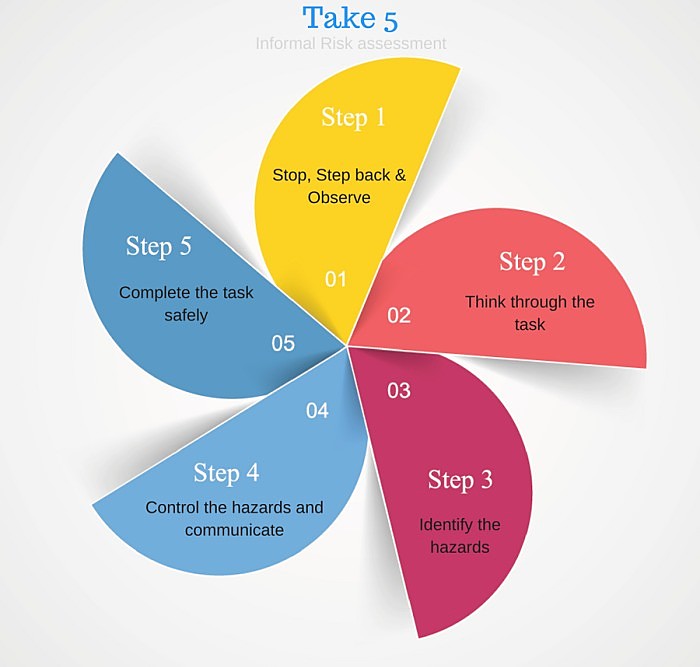

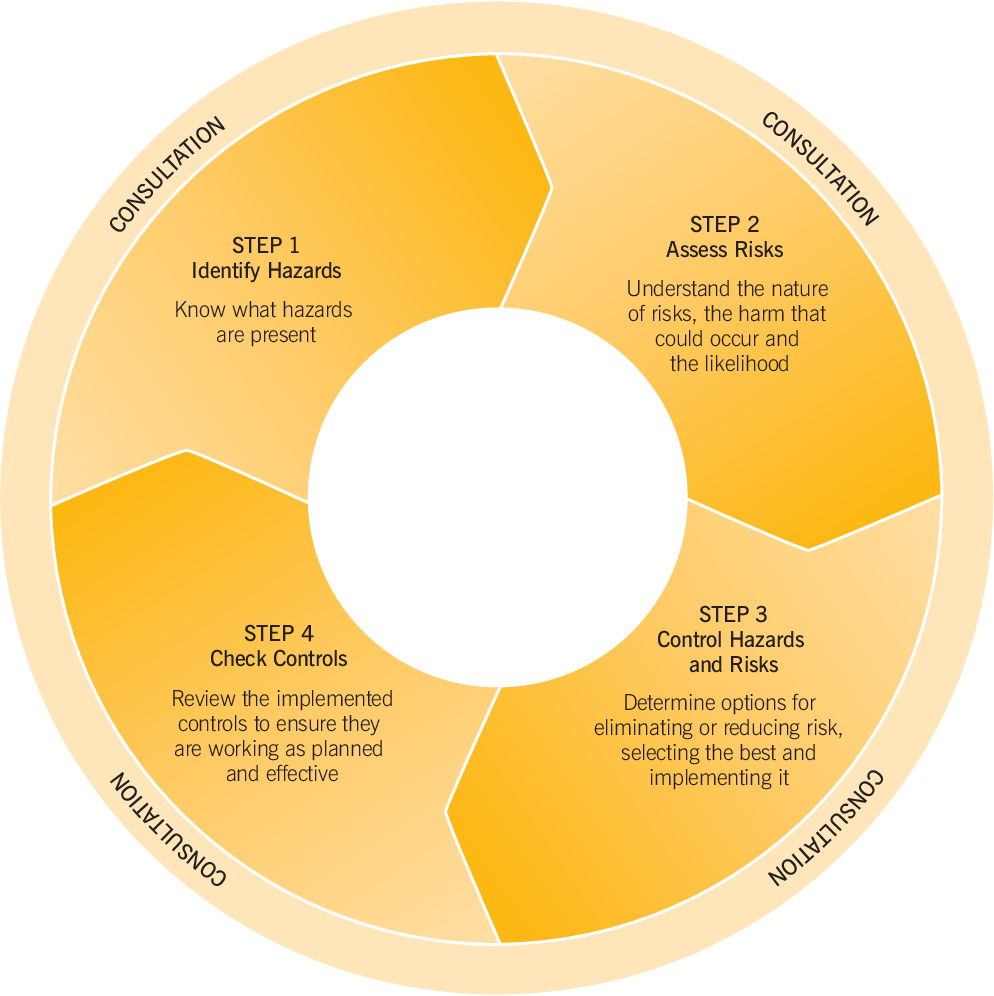

Control and to consult with workers as part of undertaking the hazard identification, risk assessment and control process It is the responsibility of workers to cooperate and comply with this policy This includes providing effective and constructive information and feedback to aid the risk management process. A Job Hazard Analysis (JHA) is an analysis of the hazards and risk associated which focus on identifying and controlling hazards Utilizing the JHA will provide a process for analyzing the work activities that will identify the tools, materials and equipment needed to develop work methods and procedures for accomplishing the task. Risk control is a step in the hazard management process It involves finding a way to neutralize or reduce an identified risk In many cases, a controlled risk is still a potential threat to employees, but the dangers associate with it have been significantly reduced Risk control is also known as hazard control.

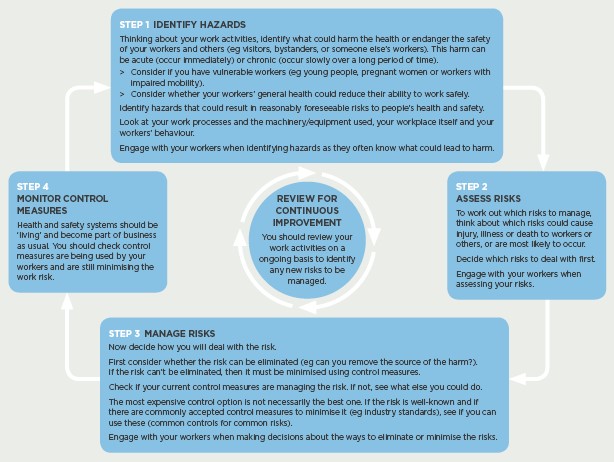

Rather, you may only discover them after they’ve caused an issue As an EHS professional, it’s up to you to find and manage these risks before they cause harm Take a look at four ways you can control hazards and risks in the workplace to protect employees and your company 1 Strengthen Your Safety Culture. Risk control is a step in the hazard management process It involves finding a way to neutralize or reduce an identified risk In many cases, a controlled risk is still a potential threat to employees, but the dangers associate with it have been significantly reduced. See below for general guidance on how to manage your work health and safety risks We also have examples and guidance to help you identify what risk looks like in your industry Using PlanDoCheckAct Following these four steps can help you with managing your work health and safety risks.

A safety risk assessment is a crucial process to ensure the safety of the workplace and to protect the health of your employees During the process of this job risk assessment , your workplace will be examined to identify possible hazards, assess the likelihood of injuries, and implement safety measures to reduce the risks in the workplace. Using the hierarchy of control 1 Eliminate the risk The most effective control measure involves eliminating the hazard and its associated risk The best way to eliminate a hazard is to not introduce the hazard in the first place For example, you can eliminate the risk of a fall from height by doing the work at ground level. This blog looks at how to use a risk management methodology to control the hazards associated with gas cylinders kept at your workplace Because compressed gases stored under pressure in cylinders present a complex range of hazards, a consistent and reliable risk management approach is necessary to ensure that all the hazards are carefully assessed and controlled.

Thus, risk can be reduced by controlling or eliminating the hazard or by reducing workers' exposure to hazards An assessment of risk helps employers understand hazards in the context of their own workplace and prioritize hazards for permanent control Download OSHA's Recommended Practices for Safety and Health Programs. Help avoid injuries, illnesses, and incidents;. The following procedure for risk management (involving hazard identification, risk assessment and control) is a practical guide for helping make all University workplaces safer for workers, students, contractors, and visitors It will help both management and workers, through consultation, to comply with the WHS regulations.

Deal with safety issues as soon as possible Record your findings It is a good practice to document what you find from your risk assessment This includes noting the hazards, how people might be harmed by them, and what's already in place to control the risk. Recognizing, assessing, controlling, and evaluating hazards is integral to the safe operation of an organization If you have served on a Joint Health and Safety Committee (JHSC) you should already be familiar with the steps in identifying and understanding workplace hazards. Evaluating and controlling hazards and risks 1 Ensure that all electrical equipment you use is in good conditionCheck the electrical cords and make sure they are not frayed 2.

Least Effective Hazard Controls Work Practice and/or Administrative Controls Work practice controls change the way workers do their jobs to reduce exposure to hazards Administrative controls address how the work is structured, such as work pace and breaks. This blog looks at how to use a risk management methodology to control the hazards associated with gas cylinders kept at your workplace Because compressed gases stored under pressure in cylinders present a complex range of hazards, a consistent and reliable risk management approach is necessary to ensure that all the hazards are carefully assessed and controlled. Using the hierarchy of control 1 Eliminate the risk The most effective control measure involves eliminating the hazard and its associated risk The best way to eliminate a hazard is to not introduce the hazard in the first place For example, you can eliminate the risk of a fall from height by doing the work at ground level.

Risk control is a planbased business strategy that aims to identify, assess, and prepare for any dangers, hazards, and other potentials for disaster—both physical and figurative—that may interfere. Review Risk Control ;. Microorganism Chemical Expose to carcinogens chemical.

Ways that a business can manage their hazards and health and safety risks include consult with workers about safety, hazards, and risk control implement a safety management system and a risk management process that are regularly reviewed consult, cooperate and coordinate with any other duty holders who have a responsibility for health and safety. Hazard control measures occur at the very end of your safety program development process This process starts with an assessment of hazard risk—and control measures are only identified and implemented later These are followed by evaluation and continuous improvement of your risk control measures to maintain an uptodate, effective safety. What is HIRA & Objective of HIRA The objective of the Hazard Identification Risk Assessment (HIRA) is to identifying and assessing the hazard associated during the construction of the project and thereby controlling the risk by implementing mitigation measures before the start of the work to avoid the incidentHIRA helps to become proactive rather than just reactive.

Risk control is a step in the hazard management process It involves finding a way to neutralize or reduce an identified risk In many cases, a controlled risk is still a potential threat to employees, but the dangers associate with it have been significantly reduced Risk control is also known as hazard control. A Job Hazard Analysis (JHA) is an analysis of the hazards and risk associated which focus on identifying and controlling hazards Utilizing the JHA will provide a process for analyzing the work activities that will identify the tools, materials and equipment needed to develop work methods and procedures for accomplishing the task. In the domain of central processing unit design, hazards are problems with the instruction pipeline in CPU microarchitectures when the next instruction cannot execute in the following clock cycle, and can potentially lead to incorrect computation results Three common types of hazards are data hazards, structural hazards, and control hazards There are several methods used to deal with hazards, including pipeline stalls/pipeline bubbling, operand forwarding, and in the case of outoforder execu.

Deal with safety issues as soon as possible Record your findings It is a good practice to document what you find from your risk assessment This includes noting the hazards, how people might be harmed by them, and what's already in place to control the risk. And help employers provide workers with safe and healthful working conditions The processes described in this section will help employers prevent and control hazards identified in the previous section. See below for general guidance on how to manage your work health and safety risks We also have examples and guidance to help you identify what risk looks like in your industry Using PlanDoCheckAct Following these four steps can help you with managing your work health and safety risks.

Biological Exposed, airborne/blood borne ;. Most Effective Hazard Controls The best way to protect workers is to remove or eliminate the hazard from the workplace using the following hazard control methods Substitution Substitute dangerous chemicals, equipment or work methods with safer and less hazardous ones to eliminatethe hazard altogether Example Replace the opentopped manual skinner used for skinning pieces of meat with an. Hazard Prevention and Control Effective controls protect workers from workplace hazards;.

Key Differences Between Risk and Hazard The following points are substantial so far as the difference between risk and hazard is concerned The term risk is described as a situation susceptible to harm, damage or loss On the other hand, hazard implies something which is a root to harm, danger or loss. •Risk Analysis – includes hazard analysis plus the addition of identification and assessment of environmental conditions along with exposure or duration –Often used interchangeably with hazard analysis –Reliability often used incorrectly as a measure of risk USPAS January 12 Controlling Risks Safety Systems. Establishing riskbased preventive controls enables you to apply a proactive and systematic approach to your food safety program through the establishment of preventive controls designed to.

Objectives of the day differentiate hazard and risk identify the types of workplace hazard create a poster showing tips for safety and health at workplace HAZARDS IN THE WORKPLACE THERE ARE MANY THINGS THAT AFFECT THE HEALTH OF A PERSON, SUCH AS ENVIRONMENT, LIFESTYLE, ETC. Process control involves changing the way a job activity or process is done to reduce the risk Monitoring should be done before and as well as after the change is implemented to make sure the changes did, in fact, control the hazard Examples of process changes include to Use wet methods rather than dry when drilling or grinding. Controlling exposures to occupational hazards is the fundamental method of protecting workers Traditionally, a hierarchy of controls has been used as a means of determining how to implement feasible and effective control solutions One representation of this hierarchy is as follows.

Risk control is a planbased business strategy that aims to identify, assess, and prepare for any dangers, hazards, and other potentials for disaster—both physical and figurative—that may. A worker is exposed to a number of hazards at work For example, a worker working in extreme hot temperatures is more likely to get dehydrated, while a worker working high above the ground is at risk of falls Hazards are often controlled via what's called the hierarchy of hazard control. Assess The Risk ;.

Reduces risk of current leakage with possible fire risks or the risk of shock current Can be used at low currents and fast response time (usually 30 mA at 30 seconds to reduce Electric Shock. O Topic 1 Hazard and Risk o Topic 2 Three Phases of Hazards o Topic 3 Hazards identification o Topic 4 Risk Assessment o Topic 5 Risk Control · This course is designed to replace 25% (4 hours) of the classroombased 2day WSQ Develop a Risk Management Implementation Plan course as part of blended learning approach. Identifying and reporting hazards in the workplace is one of the most powerful ways in which workers and companies can improve workplace safety Many workplace injuries and incidents are a result of unidentified hazards, or a lack of action on controlling the risk associated with a specific hazard.

Controlling risk and reducing hazards is one of the key obligations of everyone in the workplace, so while understanding and thinking about the hierarchy may be the focus of the safety manager, implementing and utilising the hierarchy will require the efforts of all. Objectives of the day differentiate hazard and risk identify the types of workplace hazard create a poster showing tips for safety and health at workplace HAZARDS IN THE WORKPLACE THERE ARE MANY THINGS THAT AFFECT THE HEALTH OF A PERSON, SUCH AS ENVIRONMENT, LIFESTYLE, ETC.

Hierarchy Of Controls Respiratory Protection

Osha S 5 Workplace Hazards Grainger Knowhow

Chapter 5 Safety Risk Management Safety Management Systems For Airports Volume 2 Guidebook The National Academies Press

Controlling Hazards And Risk のギャラリー

The Hierarchy Of Controls April 18 Safety Health Magazine

Risk Control

Biological Hazards And Their Suggested Controls Download Table

Hierarchy Of Risk Control Why Is It Important What Does It Mean

Controlling Hazards Road Safety At Work

Recognize Assess Control Evaluate Race Centre Of Research Expertise For The Prevention Of Musculoskeletal Disorders

Risk Assessment Hazard Analysis Expert Article Robson Forensic

Identify Assess And Control Hazards Safe Work Australia

Hierarchy Of Controls Height Safety Control Measures

Risk Management Identify Assess And Control Hazards Integrate Sustainability

Niosh S Hierarchy Of Controls Nes

Hazard Control Osh Answers

Risk Assessment

Lm Tle 7 8 Ict Pages 101 113 Flip Pdf Download Fliphtml5

Risk Assessment The First Step To Controlling Combustible Dust Hazards Wood Business

Evaluating And Controlling Hazards And Risks

Risk Assessment Farm Safety Nova Scotia Safe Farming Safe Families Safe Employees

Hazard Identification And Risk Assessment Cholarisk

Controlling Hazards In The Workplace

Methods For Controlling Hazards Ufcw Safety And Health Website

Evaluating And Controlling Hazards And Risks

Hazard Control Osh Answers

Understanding The Hierarchy Of Controls

Risk Management Hsse World

Controlling Ergonomics Risk Factors Oshacademy Free Online Training

Lesson 5 T L E Learning Module

7 Steps Controlling Ohs Hazards And Risks Worksafe Victoria 07 Download Scientific Diagram

Identifying Workplace Hazards Fit For Work

Evaluating And Controlling Hazards And Risks

Electrical Safety Hierarchy Of Controls Occupational Safety And Health

Hazard Control Osh Answers

Don T Forget Your Primary Duty Is Controlling Hazards Risks

Hierarchy Of Hazard Controls Wikipedia

Hazard Prevention And Control Occupational Safety And Health Administration

Procedure For Hazard Identification Risk Assessment And Determining Controls Iso Consultant In Kuwait

Hazard Vs Risk Health And Safety Poster Occupational Health And Safety Safety Management System

Controlling Risks Worksafebc

Lesson 3 T L E Learning Module

Hazard Identification Including Workplace Inspection Risk Assessment And Mitigation Corporate Health And Safety Government Of Yukon

Managing Workplace Hazards And Consultation In The Workplace

Minimize Work Place Hazards With Engineering Control Ppe Grainger Knowhow

Risk Assessment And Control Asa

Risk Control Vs Risk Management Video Lesson Transcript Study Com

Hierarchy Of Action Chemical Risk Management Chemical Hazards

Hazard Identification And Control Policy

What Is The Hierarchy Of Control And How Can It Be Applied arm

Controlling Risk My Top 9 Techniques Raeda Consulting

What Is Risk Assessment And Control Table Ract Clever Compliance Support Compliance System And Ce Marking Information

Hazards And Risks

3 1 Control Hazards And Risk Personal Protective Equipment Occupational Safety And Health

The Hierarchy Of Risk Control Haspod

What Is Risk Assessment And Why It Is So Useful On Board Myseatime

Risk Control Hierarchy Of Control

Evaluating And Controlling Hazards And Risks

Anticipate Recognize Evaluate Control And Confirm Wikipedia

5 5 Methods For Risk Assessment Charim

Identify Assess And Control Hazards Safe Work Australia

Managing Risks Worksafe Qld Gov Au

Integrating Risk Management Into The Design And Development Process Mddionline Com

Control Engineering Growing Role Of Human Machine Interaction In Risk Management

Hazards Health And Safety Authority

Control Measures

Hazard Control Osh Answers

Covid 19 And The Need For Robust Risk Control Strategies Can Ich Q9 Help Ivt

Controlling Risk Docest

Workplace Hazards And The Hierarchy Of Controls Tap Into Safety

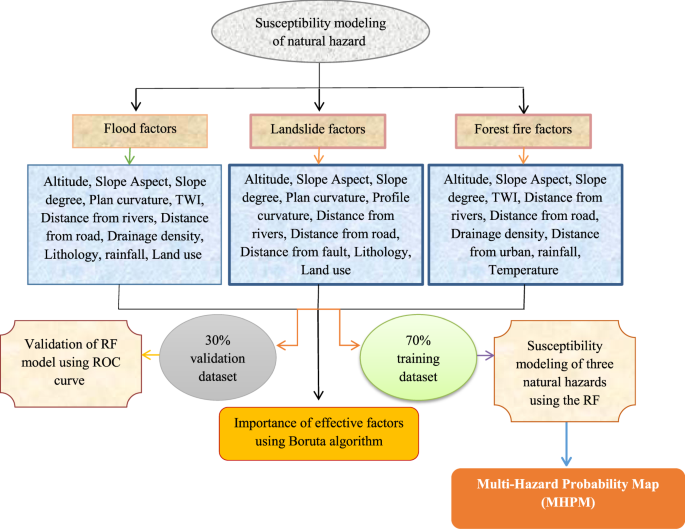

Assessing And Mapping Multi Hazard Risk Susceptibility Using A Machine Learning Technique Scientific Reports

Risk Assessment Hazard Analysis Expert Article Robson Forensic

Race Recognizing Assessing Controlling Evaluating Hazards Osg

Chapter 5 Safety Risk Management Safety Management Systems For Airports Volume 2 Guidebook The National Academies Press

Lesson 5 T L E Learning Module

Risk Management Worksafe

Nebosh Igc 2 Element 3 Musculoskeletal Hazards And Risk Control Q A Youtube

Lesson 01 Identify Hazard And Risks Computer Systems Servicing Nc Ii

Covid 19 Hierarchy Of Controls Environment Health And Safety

Hazard Risk Safety Understanding Risk Assessment Management And Perception Youtube

Risk Control

Evaluating And Controlling Hazards And Risks

Controlling Risks Hsse World

Risk And Hazard Management Health And Safety Compliance University Of Otago New Zealand

How To Apply The Hierarchy Of Controls In A Pandemic

Managing Hazards

Hazards In The Workplace Hazard Examples 9 Tested Tricks To Find Them

Hierarchy Of Control Pyramid Health Safety Handbook

Controlling Psychosocial Hazards And Risk Factors Overview

Follow The Hazards Control Hierarchy To Reduce Welding Risks 17 12 01 Ishn

How To Perform A Health And Safety Risk Assessment Safesite

Structured Safety Health And Safety Middle East

Controlling Ohs Hazards And Risks A Handbook For Workplaces Semantic Scholar

Updated Hira Hazard Identification Risk Assessment Rls Human Care

Managing Workplace Risk And The Hierarchy Of Control

Coronavirus Health And Safety Risks Helping You To Work Safely A Guide By Horizon Risk Consultancy Ltd